Increasing Legionella outbreaks underlays need for better plumbing design, mitigation efforts

Industry experts weigh in on the best ways to mitigate bacteria growth.

By Nicole Krawcke

There’s no doubt that the plumbing industry has had a hyper focus on Legionella and prevention over the past few years. Yet a simple search on Google reveals outbreaks in an Illinois prison, a Hawaiian hotel and in Riverside County, California — all within the past two months.

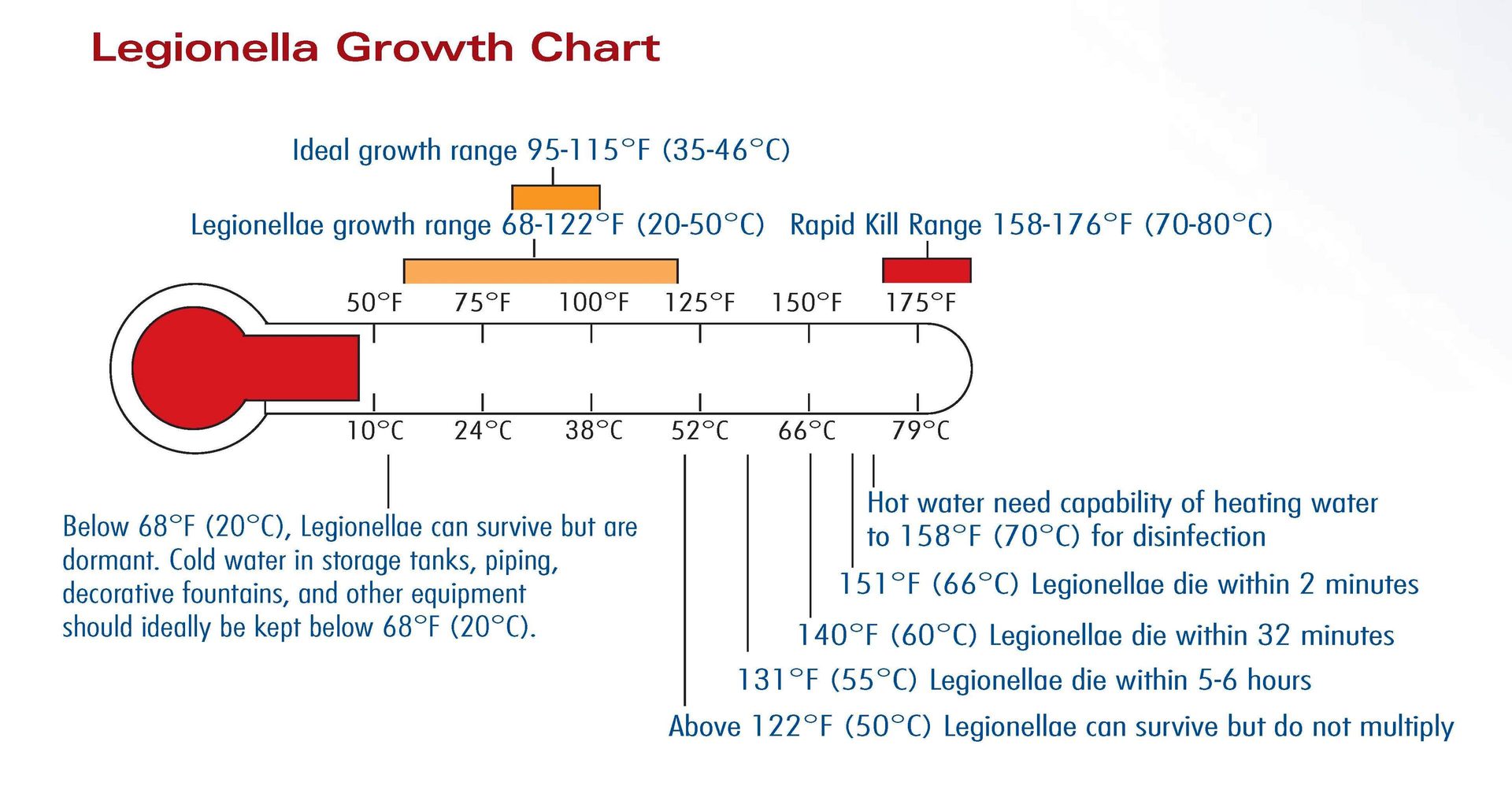

“As bacteria is formed and spread through water, the older America’s water infrastructure becomes, the chances for Legionella outbreaks increases, especially in states that have warmer climates,” explains Matt Sigler, PMG Executive Director for the International Code Council (ICC). “A common way the bacteria forms is through lukewarm water temperatures as it thrives in water that ranges from 77°F to 113° F, making it a potential breeding ground for the bacteria. Additionally, water that is stagnant within a piping system runs the risk of having disinfectant dissipate, inviting the potential growth of Legionella bacteria.”

Legionella is still very much present — and abundant — in today’s buildings, according to Bruce Fathers, senior product manager for Watts.

“A facility manager’s ability to fully eliminate the risks of this bacteria has a lot to do with proper system design and water management,” he says. “Another thing to consider is that buildings may be renovated or enlarged — work that can greatly impact a plumbing system’s susceptibility to Legionella. Building renovations are often one of the leading causes of plumbing system dead legs — when piped systems are altered, they can create unforeseen problems. Also, maintenance schedules cannot be ignored. This can happen during staff turnover.”

Fathers notes that there is also a tendency among facility managers to save energy by reducing water storage or distribution temperatures, which can allow bacteria growth.

“Another condition ideal for opportunistic bacteria growth are the use of low-flow plumbing fixtures,” he adds. “Not long ago, fixtures may have been rated at 2.5 gpm. Driven by water conservation efforts, the popularity of fixtures with ratings of 0.25 gpm to 1.5 gpm, Legionella bacteria can prosper in slower-moving distribution piping runs, protected by insulative biofilm.”

The plumbing industry is more aware, especially in health care facilities, of the risks associated with Legionella which has led to increased surveillance of the disease, says Special Pathogens Laboratory (SPL) Consulting Services Vice President Dave Pierre, who is also an ASSE-certified Legionella Water Safety and Management specialist.

“Legionnaires’ disease has always been underdiagnosed, so the increased awareness has led to us doing a better job at identifying cases of disease,” he explains. “Additionally, we have a lot of aging infrastructure, ongoing construction and renovation of buildings. We know these events and conditions can increase the nutrients in the water for Legionella and other waterborne pathogens to proliferate. Also, globally, we have increasing source water temperatures which leads to a more suitable environment for Legionella to grow. The last piece of the puzzle is our aging population. As our population ages, we have more people falling into our ‘at-risk’ groups, including growing elderly and immunocompromised populations. Did you know that the risk increases at the young age of 50?”

Water safety is key in prevention

While cases of Legionnaire’s disease have increased nine-fold between 2000 and 2018, John Lansing, plumbing designer for Portland, Oregon-based PAE Engineers, notes there is still very little oversight and regulation regarding Legionella.

“When I say Legionella, I mean, specifically Legionella mitigation practices in the building water systems,” Lansing says. “And while Legionnaires’ disease cases have increased on an international level, it’s significantly less pronounced in other countries. For example, the United Kingdom has some of the lowest cases of Legionnaires’ disease in the world. It’s still a big problem, just not to the extent it is here. It really comes back to how important Legionella mitigation practices are — that’s something they are leading globally. The UK published TM13: Technical Memo 12 by CIBSE, the Chartered Institute for Building Service Engineers back in 1988. It's basically the British equivalent to ASHRAE 12. They have had mitigation practices in place for a very long time — way ahead of us. They also have all sorts of monitoring practices and penalties. We’re starting to see that here, too, which is really good news.”

Lansing also notes it’s important to follow what is outlined in ASHRAE 188 as what buildings are high-risk. Spoilers: It’s not just health care. Multi-family residential buildings as well as senior care facilities are both considered high-risk as well — something not everyone realizes.

“For existing buildings, increasing the temperature is one of the key things for sure,” Lansing says when it comes to Legionella mitigation. “It’s existing, so we can’t change anything on the design side, of course. So what we need to do now is commission the domestic hot water system, and by commissioning, I mean ensure the temperature is maintained throughout the system above 120° F —and that number comes from ASHRAE 12. Once that is completed, it’s all about monitoring. Testing is really key.

“Let’s take a look at Denmark for example,” he adds. “Denmark requires a minimum storage temperature of 140° F, and a minimum piping temperature of 122° F. Those numbers match what the UK uses identically. However, Denmark has six times the amount of Legionnaire's disease cases. Now, why is that? I don't think anyone can conclusively say why. But a recent study published in a Danish plumbing engineering magazine last year found that on a survey of a 100 buildings, two-thirds of those buildings were operating below that minimum temperature. So regulation, monitoring and implementation are imperative because the standard is no good if no one's following it.”

John Mullen, director of technical services for IAPMO, notes that Legionella prevention methods in existing buildings may be different each time. However, the industry can focus on educating building operators on current best practices by helping them modify outdated standard operating procedures as it relates to building water systems.

“Performing in-depth reviews of normal building operating parameters on a regular basis allows building owners to keep a pulse on the efficacy of their programs,” Mullen explains. “By doing the hard work and performing program validation on a continuous basis, operations teams will feel more confident in their understanding when it comes to mitigating the risk or managing an outbreak.

Considering my time spent working in critical environments, I know very well that facilities operation teams have a lot on their plate. The resources available to a building management teams are often severely stressed and tend to lack innovation because of that daily stress.

“If we can fix this gap with continuing education and provide resourceful platforms for discussing the perils of water management, we would all be better for it,” he adds. “Open sourcing information as it pertains of new investigatory tactics and common areas of neglect in critical environments will surely sharpen everyone’s swords.”

According to Fathers, the best way to eliminate Legionella bacteria is for facility managers to have a multi-barrier systems approach and water management plan.

“Its key facets include higher storage temperatures with ASSE 1017 thermostatic valve protection and proper distribution temperatures driven by legionella mitigation guidelines, with ASSE 1016/1069/1070 thermostatic valves at all points-of-use,” he says. “In addition, facility hot water management sanitation should include ultraviolet (UV) treatment, point-of-entry (POE) and point-of-use (POU) filtration, and treatment regimens liker copper silver ionization, and chlorination. With the growing popularity of digital mixing stations – like IntelliStation – hot water purging and mitigation protocols can be met with ease. A digital mixing system can send highly-heated water out through distribution piping to all points-of-use. Typically this is accomplished in a facility in a very deliberate fashion, zone by zone, to assure thorough sanitization and safety of occupants.”

Pierre notes that Legionella bacteria enter buildings when — and if — the source water brings them to our door. “The rule of thumb is about half of large buildings will be colonized with Legionella bacteria. For example, our study on high rise buildings in New York City showed only 54% (15/28) were colonized with Legionella. Once Legionella has colonized a building warm water system, there is no “silver bullet” or “one size fits all” to prevent the risk of Legionella.

“Implementation of a robust water safety and management plan and validating that plan with routine testing for Legionella is the best way to understand and manage the risk,” Pierre continues. “The control measures, corrective actions and mitigation methods in the water management plan should be evidence-based with publications or references showing efficacy against Legionella. One of the most important things to remember is that we don’t need to eradicate Legionella from our building water systems to reduce the risk of disease. Our goal is zero cases of disease, not necessarily zero Legionella. For a building with Legionella colonization, it can be virtually impossible to completely eliminate all Legionella, and thankfully, that unrealistic goal is not needed to reduce the risk of disease occurrence.”

Best practices for plumbing design

There are several best practices for plumbing engineers to help prevent Legionella growth when designing new plumbing systems.

“Engineers should install ports throughout the water supply infrastructure to enable sampling and testing of the water to help better monitor the temperature and disinfectant levels,” notes Sigler. “Additionally, plans should incorporate double elbow fittings — such as Viega’s double drop elbow — to maintain proper water flow from either side of the plumbing loop . Furthermore, at a minimum, pipes should be installed with proper insulation in accordance with the 2021 IECC Section C404.4 for non-residential buildings and Section R403.5.3 for residential buildings.”

Sigler also points out that engineers should eliminate low-flow areas and minimize the distances between plumbing fixtures and hot water sources.

“In the International Plumbing Code (IPC), the maximum length for hot or tempered water piping must not exceed 50 feet from the source to the fixture,” he explains. “This helps reduce the possibility of bacteria growth while limiting the amount of energy needed to maintain water temperature.”

Another consideration to keep in mind, Sigler adds, is the distance between a building and water treatment plant. “The further a building is from the plant, there may be a need for a supplemental disinfectant system to ensure there is sufficient disinfectant residual throughout the water supply system.”

Fathers sees hot water recirculation as a critical weapon in battling Legionella.

“One thing to always look for and to eliminate are plumbing dead legs where warm, stagnant water can fester, serving as an ideal breeding grounds for legionella growth,” he says. “Also, it’s important to properly size all equipment that in a safe and efficient plumbing design. Call it system optimization. This may entail a thorough inspection of a facility’s entire plumbing system — from the backflow device at entry to the water heater to distribution piping, and even sanitization of small aerators at all points of use — they often harbor bacteria.”

According to Mullen, the most common design decisions being made relating to Legionella prevention at present come in the form of automatic faucets and valves, with advanced scheduling tools that assist in flushing aged water.

“These components are typically associated with building maintenance systems and allow centralized control by building operators, whether onset or remote,” he explains. “Simple, yet often overlooked design enhancements include laminar flow aerators to help ease common areas of stagnation or considering tankless hot water storage with plate and frame heat exchangers in lieu of tank type.”

Mullen also notes that unfortunately, cost plays a large role in design decisions.

“Often, without the knowledge of these horror stories of legionella outbreaks, the wrong choices get made,” he says. “Value engineering exercises early in the bidding process tend to scrap these new aged components from the design, leaving the building exposed to proliferation. The barrier of entry on these components are slowly starting to come down, and this will in turn advance the popularity of installation leading to more data collection and interpretation.”

Additionally, tools such as IAPMO’s Water Demand Calculator are helping plumbing engineers design smarter, safer and more sustainable systems with smaller pipe diameters.

“For years, we’ve used pipe size in ways we know do not represent the way we live today,” Mullen says. “With the increased popularity of digital meter faucets, water conserving fixtures and intuitive building designs, we simply don't need the demand we once thought we did in various environments. The Water Demand Calculator includes a modern approach to designing water systems, based upon an updated probability boost. This engineering tool is the most interesting advancement of plumbing design we've seen in decades, by engineering building systems with Legionella mitigation at the tip of the spear, professional engineers and certified plumbing designers can provide cost effective solutions to their clients that does not require the additional cost of a broadband connection or dedicated power.”

Currently, the Water Demand Calculator is used for residential plumbing design; however, an updated version for commercial plumbing is currently in the works. Mullen expects the commercial version will be released within the next year to two years.

Lansing also recommends limiting the length and diameter of uncirculated branch piping to fixtures.

“For decades now, the industry’s been installing low-flow fixtures with high flow piping,” he says. “When I say high flow piping, what I'm really referring to is oversized piping, which is going to lead to more stagnation and reduced water quality, which is thought to be a contributing factor of Legionnaires’ disease cases. The problem is necessarily low-flow fixtures, but if we change one thing, we have to change other things. It seems to me that’s potentially just as much of a problem of poor design practices, not only from an individual perspective, I would say even mostly from a delayed response from the industry in developing an updated pipe sizing method. To be honest, I don’t see that as the industry’s fault either. We don’t have nearly the amount of funding and focus that we did back when Dr. Hunter developed the Hunter’s Curve in 1940.

“When that was done, it was like ‘We solved water pipe sizing forever, we don’t have to revisit this for at least 200 years,’” he continues. “That’s obviously not the case. There’s been a lot of movement on using the UPC’s Appendix method.”

Pierre believes the most common consideration for designing new plumbing systems is not necessarily specific products or components, but rather the compatibility of the components and materials with the facility’s water management plan.

“We should consider how the materials and components we select will impact water safety at the facility,” he explains. “Working with the water management team is essential to understanding these elements. For example: Are components and materials able to withstand high temperatures or a chemical disinfection, if the plan includes these as corrective actions? If our water management plan includes sampling or monitoring of the hot water return, or storage tanks — has the design incorporated sampling ports or temperature gauges?”

What’s next?

So what’s next in terms of Legionella prevention and mitigation? Mullen notes that engineers should keep an eye out on the advancement in critical system automation and the use of artificial intelligence designed for the built environment.

“There’s a massive opportunity for data collection from these emerging technologies, and partnerships will be crucial to ensure that the information does not go to waste. The intellectual property extracted from these tools will undoubtedly be something we as an industry have a need for, considering the currency field data has in research and development. The more intelligent our buildings get, the more intuitive plumbing components and equipment will have to become to function in these ecosystem systems. If we don't continuously stay ahead of these innovations as engineers and installers, the adoption of these systems will see an unnecessary stifling effect. The industry is managing very well with the growing pains related to digitalization, and that makes me very hopeful.”

Fathers agrees that engineers will see greater value through evolving IoT technologies — especially in terms of how data can be interpreted and used.

“Some very surprising things are beginning to emerge as a result of the rich resources we’re finding with all this new data — call it ‘building profiling,’ he says. “Engineers, system designers, building owners and data analysts alike are finding it possible to learn so much more about the buildings in which we live and work — data that now allows us to better-design systems, fine-tune system performance, streamline or tailor maintenance schedules or more accurately size system components — even down to details like better sizing of mixing valves, precisely matched to their intended use.

“There’s always been a predisposition to oversize systems hot water systems, such as valves, pumps, etc., to ensure adequate hot water at all times,” Fathers adds. “But now, if data confirms that an average 300-bed hospital consumes a certain amount of domestic water, it allows facility designers to design building systems with far greater accuracy and efficiency.”

Sigler points to the use of treated wastewater inside of a building becoming more of a common practice. “It is important to ensure that proper backflow protection is provided between potable and non-potable water sources as cross connections can introduce Legionella bacteria into the potable water supply system,” he explains. “Additionally, algae and bacteria growth patterns should be monitored at treatment facilities nationally.”

Lansing suggests engineers should produce more case studies going forward.

“If you’ve designed and implemented a system that addressed the issue of Legionella growth well, document what you did and get it out there as a case study,” he says. “It doesn’t have to be perfect. We need as much information as possible assessing the effectiveness of these strategies so we advance together as an industry. We need to be implementing measures, studying the effectiveness and then circling back and modifying the approaches accordingly. That's the only way to move forward without making arbitrary decisions that could impact other aspects of public health, like thermal injury, which may not appropriately address the risk of Legionnaire's disease. There are a lot of different standards and a lot of different risks, and it’s really important that we are taking all of them into context as we move forward with standard strategies.”

Pierre notes that engineers should look for the UPC and UMC to incorporate water management into its building and plumbing codes. “This will place a larger role on designers and engineers to consider Legionella and water management in the design phases. Additionally, the increased awareness could possibly lead to more legislation. At least six states have introduced legislation addressing the risk of Legionella in our building water systems, including the state where it all began — Pennsylvania.”

ABOUT THE AUTHOR

Nicole Krawcke is chief editor of Plumbing & Mechanical and PM Engineer. She can be reached at krawcken@bnpmedia.com.